Integrated Solution 1

Space Optimization

Request

Even if they enjoy rapid developments, some industrial realities can have difficulties to accompany structural amplifications to the new production volume. Therefore it is necessary to use in the best way possible the availvable space.

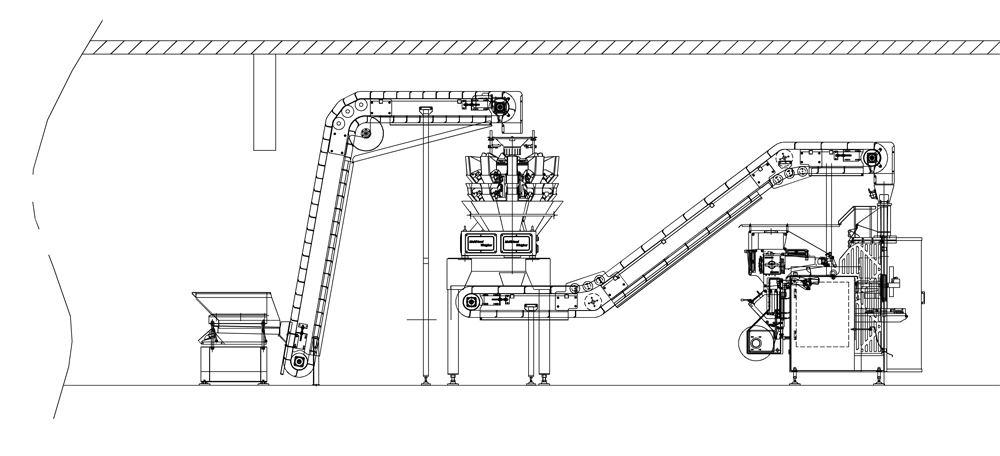

In this example, the area at disposal for the installation of the packaging plant was not only very narrow, but also the height of the factory was particularly small. Besides this there was 2 special requirement by the customer: to integrate in the plant some machines already in his possession and to made the system compatible with the different products and bags programmed in the future.

Analysis and Solution

After an inspection and accurate measurements, our technicians have drawn up a layout study, which consider the various factors: it was fundamental not only that the occupied volume was taken into account, but also that the plant was adequate to the new increasing production condition.

For this reason has been chosen a decentralization: instead of vertically combining the multihead weigher of the customer with the new packaging machine (impossible, considering the height of the factory lower than 4 mt.), thanks to the use of custom elevation belts, it has been possible to feed the plant continuously, without losing precision.

- The loading hopper of the customer receives the product and distributes it onto the elevator belt.

- The fixed speed elevator belt with horizontal zone feeds the weigher.

- This weigher has been equipped with a timing hopper, which collects the weighings and distributes them onto the below belt.

- The elevator belt, with horizontal zone, but with step advancing controlled by a photocell, collects the weighed product by means of a spondaflex belt with listels.

- An intermittent motion vertical packaging machine receives the weighings and package the product in the different requested sizes.

The choosen packaging machine, model MX600, has been customized in order to use the labelling machine of the customer directly in the forming zone and predisposed for the use of other accessories considering the bags foreseen in the future.

By means of a series of photocells along the whole packaging chain, interfaced directly with the touch-screen control panel of the packaging machine, it has also been possible to automate and fully control the production flow.

* The images shown are indicative and represent a demonstration version of the machine. The sales version presents a product outlet conveyor and a protection tunnel adequately conformed according to current European regulations.